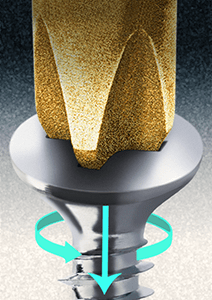

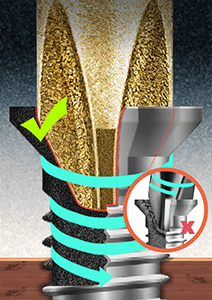

Macfix process to ensure 100% precision blade tip size according to ASME, DIN ISO.

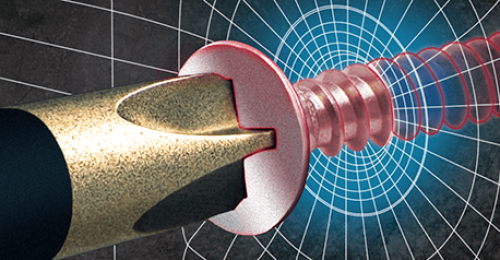

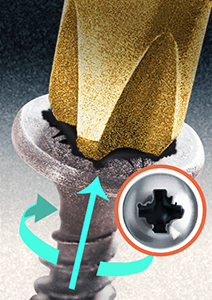

Its super friction force makes the tool optimize and maximize its torque during the actual working process.

Tighten screws with ease, result in labor saving at least 4 times smaller than normal tip screwdrivers.

It effectively reduces cam-out issue on screw and also avoids slipping-out problem.

Its roughness feature allows easy removal of the screw with excellent friction between tip and screw.

Anti Cam-out function would protect both the driver head and screws from damage.

Macfix has developed various types of tools for the working environment whereas electrical safety is of the top concern.

You will find tools such as Screwdrivers, Wrenches, Sockets, Pliers, Cable Knives, Tweezers and Scissors are available for working at live circuit mode.

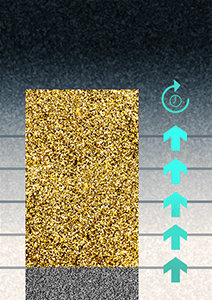

Test height according to the sample weight (kg), impact test done at room/ low temperature. No damage, fall off appear on the insulating layer.

After being subject to a pressure of 20N, a temperature of +70°C and current at 5,000 volts for 3 minutes, no pressure marks of lift-off must appear on the insulation.

After a temperature of (70±3°C) and subject to a specific force and duration in room temperature. There must be no displacement or damage to the insulation.

The insulation shall stays firm and remain snug against the tool body between temperature of -40°C to 70°C for further test requirements.

Subject to 10KV Voltage in Water Bath/ or Steel Ball for 180 seconds. There must be no holes, sparks, flashes on the insulation, and the current in the circuit shall not exceed 1mA.

2cm away from the burner, burn vertically for 10 seconds. The flame height on insulation shall not exceed 12cm within 20 seconds of continuous burning.

VDE stands for ‘Verband Elektrotechnik”. The VDE Testing and Certification Institute is a nationally and internationally accredited organisation for testing and certification of electrical engineering devices, components and systems. They test them for safety, electromagnetic compatibility, and other product properties. VDE conforms to the VDE regulation or European or Internationally harmonized standards. They confirm the compliance with the safety requirements of the respective guidelines.

The quality, construction and even ergonomics meet with the protective requirements of the applicable European Union Directive.

Copyright © 2020 MACFIX TOOL GROUP. All Rights Reserved.